Digital frame measuring (DFM) is revolutionizing car body repairs in the automotive industry by providing precise, efficient measurements for OEMs and repair shops. This technology streamlines processes, reduces human error, and improves communication, setting standards for consistent, high-quality repairs. DFM ensures accurate data capture, enhances workflow efficiency, and facilitates superior customer satisfaction through reliable outcomes, especially in complex collisions.

In today’s digital era, understanding and leveraging digital frame measuring technology is crucial for Original Equipment Manufacturers (OEMs) aiming to enhance repair precision and efficiency. This innovative approach supports OEM repair specifications by providing accurate measurements and data, streamlining processes, and reducing errors. By implementing digital frame measuring, OEMs can ensure consistent quality, improve customer satisfaction, and maintain competitive advantages in a rapidly evolving market. This article explores the technology’s benefits and implementation strategies.

- Understanding Digital Frame Measuring Technology

- Benefits of Using Digital Frame Measuring for OEM Repair Specifications

- Implementing Digital Frame Measuring in Repair Processes

Understanding Digital Frame Measuring Technology

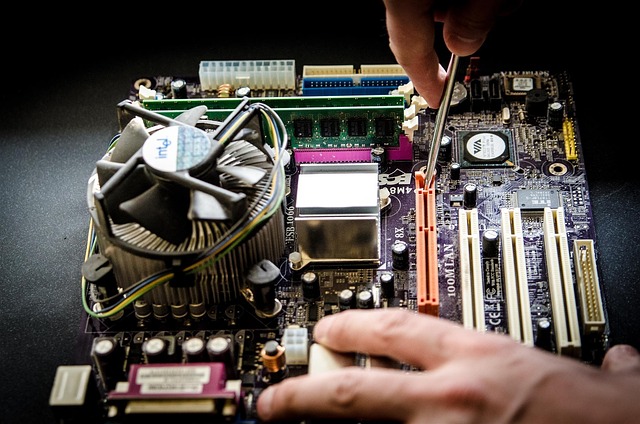

Digital Frame Measuring technology is a game-changer in the automotive industry, especially for Original Equipment Manufacturers (OEMs) and car body repair shops. This innovative process involves using advanced digital tools to accurately measure and capture the dimensions of vehicle bodies, providing precise data for repairs and replacements. With digital frame measuring, technicians can swiftly assess the state of a car’s bodywork, ensuring every detail is accounted for during the repair process.

This technology offers several advantages over traditional methods. It streamlines the measurement process, reducing time and potential human errors. The digital data captured allows for better communication between OEMs, vehicle manufacturers, and car body shops, setting the standard for consistent and high-quality car body repairs. By employing this advanced technique, vehicle body shops can deliver more efficient services, ensuring customer satisfaction with accurate, OEM-spec repairs.

Benefits of Using Digital Frame Measuring for OEM Repair Specifications

The adoption of digital frame measuring technologies has revolutionized the way Original Equipment Manufacturers (OEMs) and auto body shops approach car damage repair and collision repair services. This innovative tool streamlines the process by providing precise measurements, ensuring accuracy in estimating and executing repairs. With digital frame measuring, technicians can quickly capture detailed data on vehicle frames, including angle, bend, and twist, which are critical for restoring a vehicle to its pre-accident condition.

Moreover, digital frame measuring enhances efficiency and reduces errors in the repair process. By digitizing measurements, it becomes easier to compare against OEM specifications, facilitating more consistent and reliable outcomes. This precision is particularly valuable in complex collision repairs, where minimizing deviations from original design parameters is essential for safety and performance. Ultimately, digital frame measuring empowers auto body shops to deliver superior quality car damage repair services while maintaining customer satisfaction.

Implementing Digital Frame Measuring in Repair Processes

Implementing Digital Frame Measuring in Repair Processes has revolutionized the way Original Equipment Manufacturers (OEMs) and their authorized repair facilities handle vehicle dent repair and other auto collision repairs. This advanced technology offers precise measurements, ensuring that every repair is executed with utmost accuracy. By digitizing the frame measuring process, repair technicians can access real-time data, which streamlines the entire workflow.

Digital Frame Measuring provides a level of detail and consistency not achievable with traditional manual methods. It enables vehicle repair services to identify even subtle deviations in the vehicle’s structure, crucial for achieving a perfect finish in auto collision repair. This meticulous approach, coupled with the efficiency gains from digital technology, has elevated the standards of precision in the industry, making repairs more reliable and lasting.

Digital frame measuring technology has proven to be a game-changer for Original Equipment Manufacturer (OEM) repair specifications. By accurately and efficiently capturing vehicle frame data, this innovative method streamlines the repair process, ensuring precision and consistency. The benefits are clear: improved quality control, reduced time-to-market, and enhanced customer satisfaction. Implementing digital frame measuring in repair operations allows OEMs to stay ahead of industry trends, meet evolving customer demands, and ultimately revolutionize automotive after-sales services.